SINCE 2014

Transmission parts solution provider

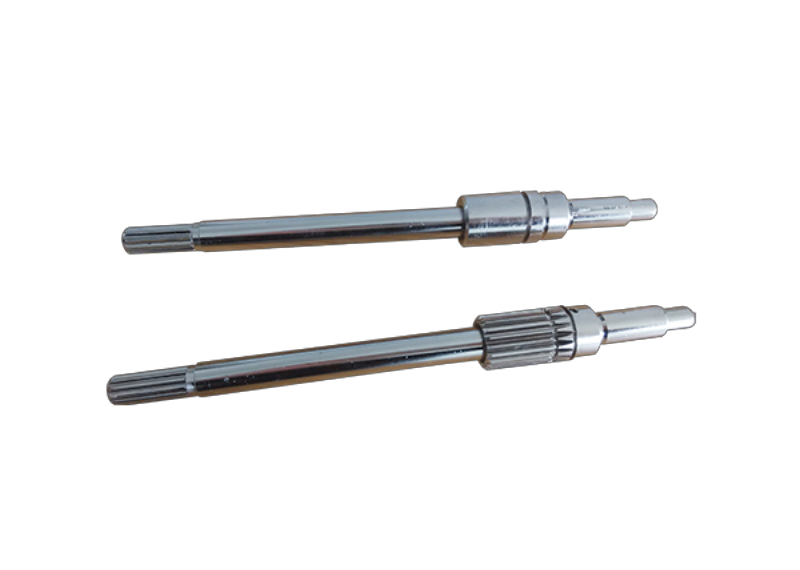

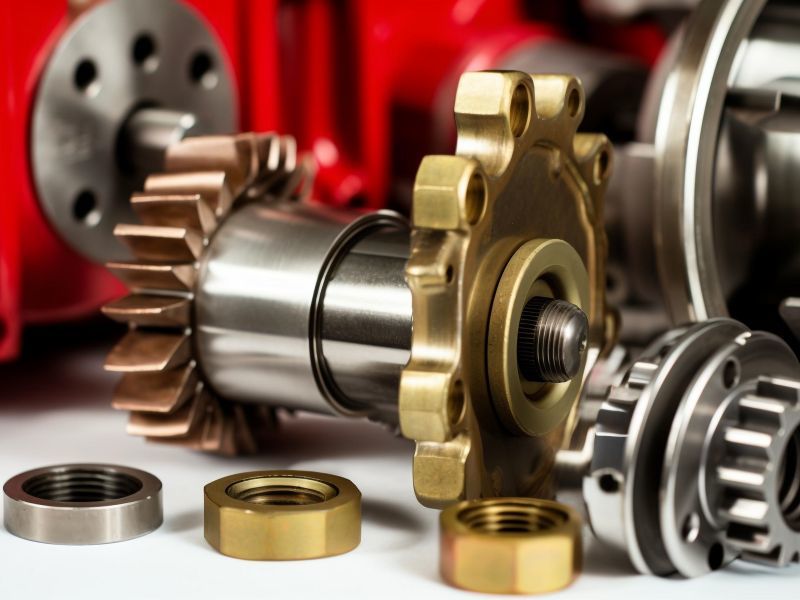

Changzhou Xinjinyu Transmission Technology Co., Ltd. (formerly Changzhou Olister Electric Co., Ltd. Gear Division) is a high-tech enterprise specializing in R & D, manufacturing and sales of gear shafts, worm gears, high-precision shafts and other transmission parts, as well as reducers and reduction motors. The company has advanced automated CNC machining equipment, Japan imported gear testing center, and has a complete quality management team, creative and pioneering R & D team. The products are located in the design and manufacture of medium and high-end transmission parts, with high precision grade. The products are widely used in motors, reduction motors, reducers, special mechanical equipment, logistics transportation and other fields.

Company industry experience

High-tech products

Patent Certificate

Partners

Product Series

Professional R & D, manufacturing, sales of gear shaft, worm gear, high precision shaft and other transmission parts as well as reducer, gear motor

Strong execution

Professional R & D manufacturing and sales of gear shaft, worm gear and other transmission parts as well as reducer, gear motor

News Dynamics

Professional R & D, manufacturing, sales of gear shafts, worm gears, high-precision shafts and other transmission parts, as well as reducers, geared motors, etc.

2024/01/17

Several Methods of Reducing Gear Noise

There are many reasons for gear noise. In most applications, the noise generated by gear rotation and vibration is acceptable. But under high load and high speed, noise is usually a problem to be solved. If you have ever encountered such troubles or customer complaints, the following suggestions are for your reference.

2021/06/16

Which kind of lubricating oil is better for plastic gears

Plastic itself has self-lubricating properties, the application of plastic gear with oil lubrication, grease lubrication and no lubrication. It has good adhesion, protection and wear resistance, and has good compatibility with polycarbonate, polyacetal resin, ABS resin and other plastics.

2021/04/29

Reduction gear modification and MASTA simulation

The elastic mechanics of materials makes the gear set meshing, the main and passive gears can be simplified to a cantilever beam model rotating around the axis line, which will produce bending deformation under load, and there is elastic deformation in the contact area of the tooth surface.

Cooperation Customers

Professional R & D, manufacturing, sales of gear shafts, worm gears, high-precision shafts and other transmission parts, as well as reducers, geared motors, etc.

Contact Information

Mobile:86-13813562229

Telephone:86-13813562229

E-mail:Honest118SR@163.com

Address: 65-21 Xinggang Road, Zhonglou Economic Development Zone, Changzhou City, Jiangsu Province

Focus on us

Copyright 2024 Changzhou Xinjinyu Transmission Technology Co., Ltd. All Rights Reserved